Early 2022, JCEM Group announced the acquisition of TAG GmbH Germany, and with it 30 years of excellence & superior engineering in the field of Mini-pleat Systems. The construction of a new JCEM – TAG manufacturing facility near Berlin is scheduled to start soon and be completed in early 2024.

Optimally positioned for the future

The acquisition builds on a long-standing relationship between JCEM GmbH and TAG GmbH. The combination of the JCEM & TAG machinery for synthetic mini-pleating has proven to be the world’s most efficient & versatile system on the market today. The union of companies is beneficial for mutual and new customers, as they now have access to the combined resources and services of both companies across all locations. Additionally, the acquisition will enable simultaneous growth, attraction of new talent, and realizing even larger and more complex projects. For JCEM GmbH and TAG GmbH, it is the strategically most sensible and logical time for a new phase, which will be implemented in a capital-strong, innovative, and speedy manner. The acquisition has optimally positioned both companies for the future and will jointly embrace the boundless opportunities offered by the Filtration market.

Lineup with all types of pleating equipment

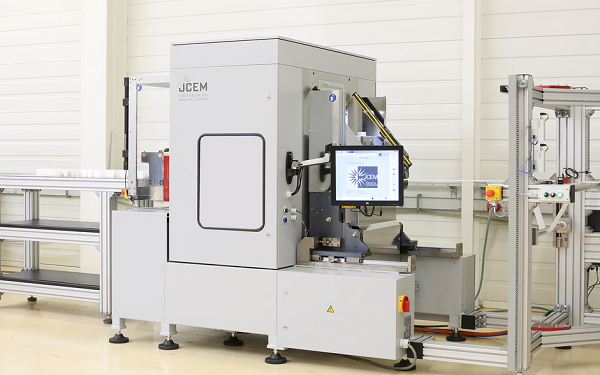

JCEM Group, including JCEM GmbH (Switzerland), TAG (Germany) and JCEM Inc. (USA), is the global leader for all types of pleating equipment, offering the world’s most innovative, efficient, and robust pleating systems available. Our lineup consists of the latest P7 model offering world-record pleating speeds, Blade & Mini Pleat Systems, Cabin Air lines, Custom requirements, and more:

- CNC Mini-Pleat lines for Glass & Synthetic with Glue Bead separation

- P6 “Power Pleater” offering extreme pleat compression for the heaviest wire or Stainless mesh pleating applications, from 3mm – 300mm.

- Cabin Air lines in combination with our High-Speed P7 pleating machine for the world’s fastest Blade Pleating/Cabin Air production line (incl. Auto splicing and web accumulation)

- Servo-Driven Unwind systems, Automatic Splicing, Integrated Web Alignment, Servo Web Festooning, Slitting systems, Pleat Pitching, Aluminum Separator automation, Post-Pleat Cutting, Servo Cross Cutting

For more information, visit www.jcem.group