Electronic waste contains valuable metals enclosed in material compounds or alloys. At present, recovering these metals needs sophisticated and energy-consuming processes. Engineers from Iowa State University, USA, developed a process to recover pure metals from waste by combining controlled oxidation and relatively low temperatures.

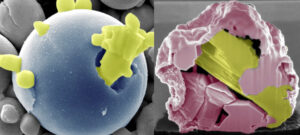

The researchers were inspired by nature’s work to build spicy structure in caves, by reaction of special rock components with the water from the air inside the cave. In the application presented here, the researchers dealloy a metal by slowly moving the most reactive compounds to the surface where they form stalagmite-like spikes of metal oxides. That leaves the least reactive compounds in a purified, liquid core surrounded by brittle metal-oxide spikes “ to create a so-called ‘ship-in-a-bottle-structure,” said Martin Thuo, the leader of the research project and an associate professor of materials science and engineering at Iowa State University.

“The structure formed when the metal is molten is analogous to filled cave structure such as stalctites or stalagmites,“ Thuo said. “But instead of water, we are using oxidation to create these structures. He and the engineers in his research group want to control exactly how and where the components fall apart, or dealloy, by tuning oxidation via temperature, oxidant partial pressure, time and composition, in a balance between reactivity and thermal deformation. The process temperature lies in the range of 260 – 370 °C, which makes operation easier and probably less energy consuming as traditional electrochemical or high-temperature methods.

A paper describing the new technology, “Passivation-driven speciation, dealloying and purification,” has recently been published by the journal Materials Horizons. University startup funds and part of a U.S. Department of Energy Small Business Innovation Research grant supported development of the technology.

The new technology works in two ways: It can bring the most reactive components to the surface, forming stalagmite-like spikes (left); and it can leave the least reactive components in the core surrounded by metal-oxide spikes, creating a “ship-in-a-bottle” structure (right). Photo courtesy of Martin Thuo.

Original publication: “Passivation-driven speciation, dealloying and purification,” Materials Horizons, published online Jan. 19, 2021, https://doi.org/10.1039/D0MH01832E