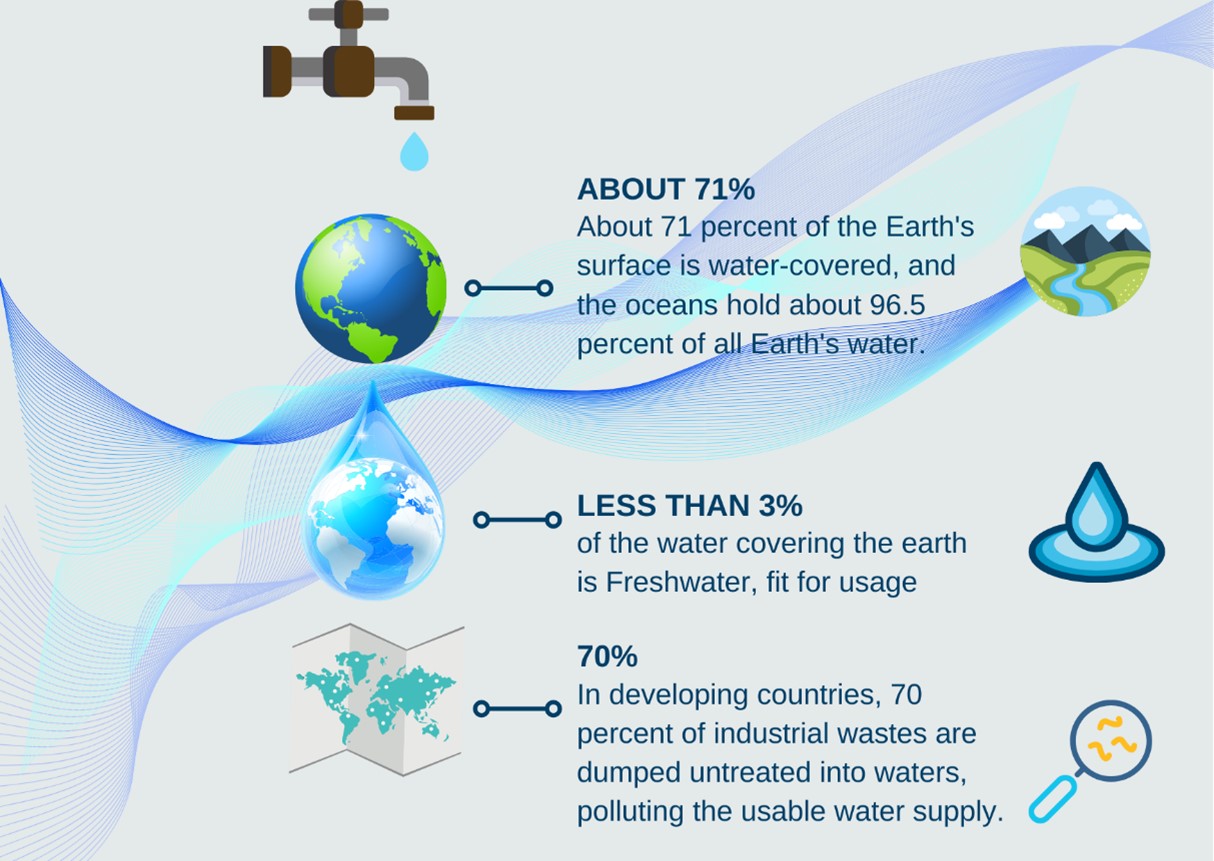

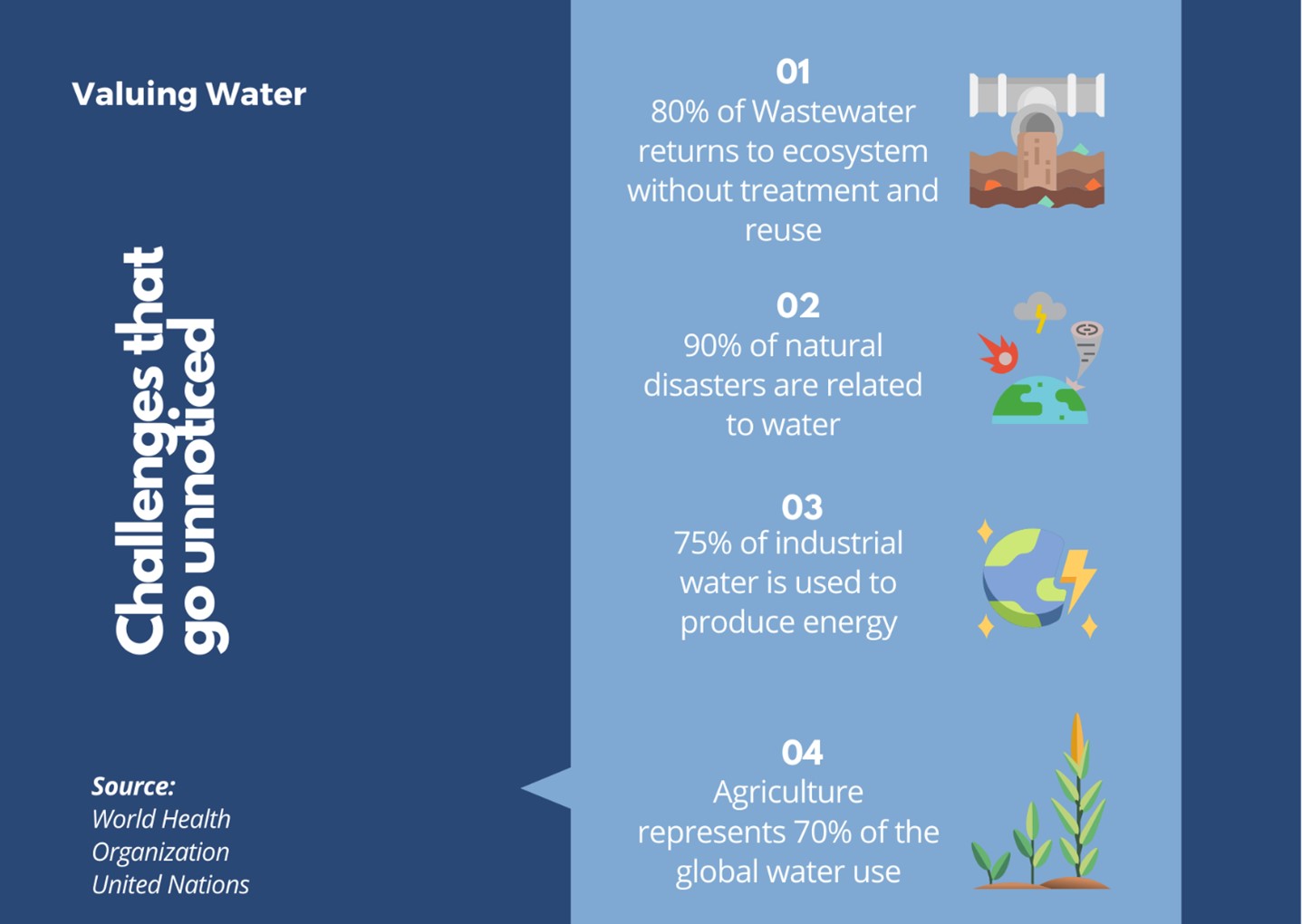

Clean water is a life-giving resource. This requirement has been recognized since the dawn of civilization, when civilizations would form and live near clean water supplies. Only around 3% of the planet’s water is available for drinking and agricultural use, as it is stored in the oceans as saline water that is unfit for human consumption or agricultural use. Pesticides, heavy metals, biological species, pharmaceutical residues, and polyfluoroalkyl compounds have all been found in water samples . To avoid detrimental effects on the environment and human health, contaminants/water pollutants must be removed. This is a difficult operation as the wastewater streams are the harshest and toughest waters to treat due to their varying contamination levels.

Industrial wastes are often characterized as having high organic content that can come from solvents, oils, fats, greases, and other materials used or derived in industrial processing. These wastes can also have a variety of dissolved salts and metals, which make treatment difficult due to issues with scaling and osmotic pressure. Typical treatment processes utilize particle filtration technology, softening, RO, evaporation and crystallization to achieve ZLD; however, this can be a very complex treatment process and the evaporation and crystallization processes are very expensive.

ZLD (Zero Liquid Discharge) means to remove all the liquid waste from a system. ZLD was based on standalone thermal processes, where wastewater was typically evaporated. Membrane process is incorporated into thermal process to improve energy and cost efficiencies. Through recent developments in fouling resistant membranes, these high organic content wastewaters can be treated with better stability. Another key development has been salt-selective nanofiltration membranes which can separate the salts into chloride rich and sulfate rich streams so that the resulting brine can be potentially reused. Finally, new ultra-high-pressure membranes have been developed which allow economical brine volume reductions and minimize the use of expensive evaporation processes.

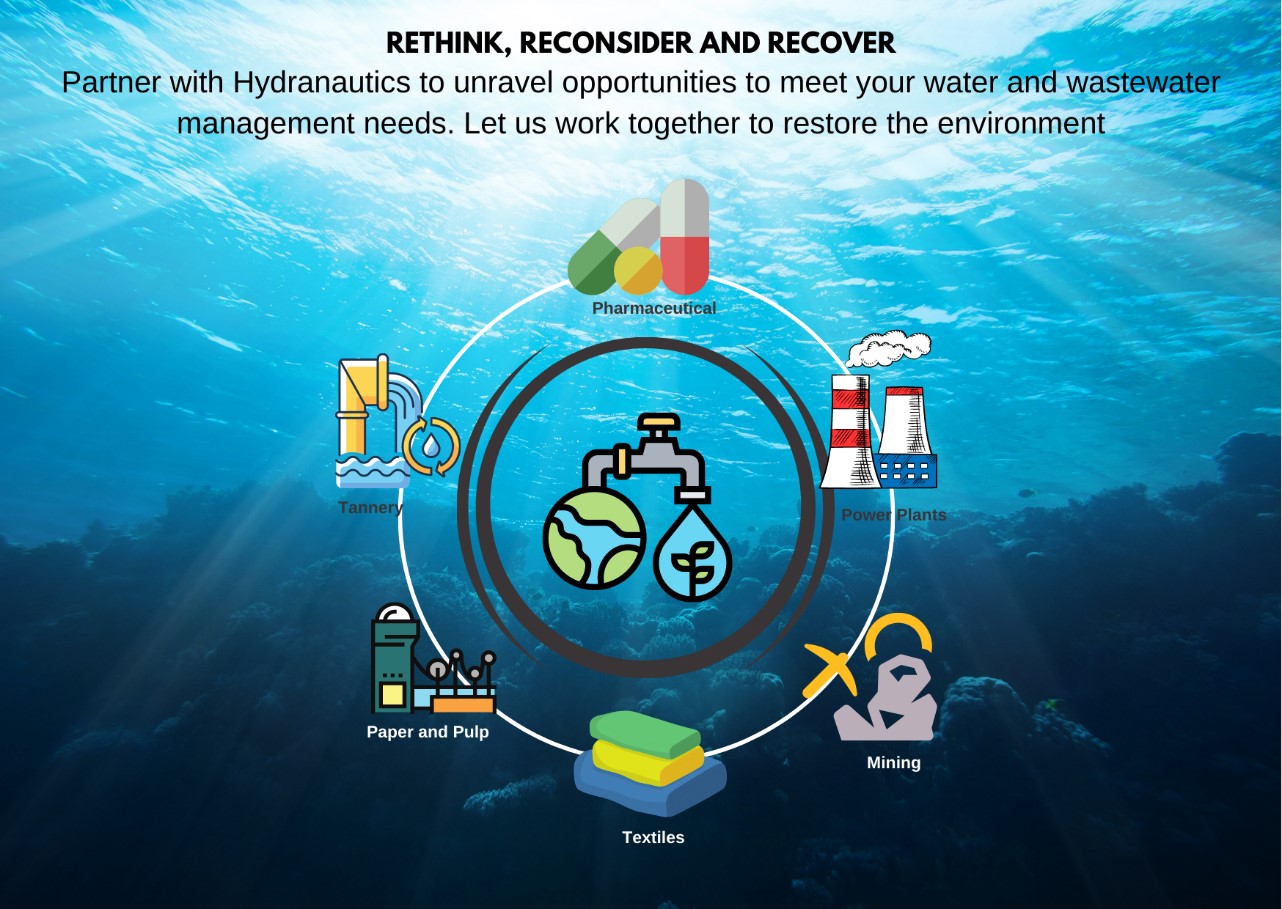

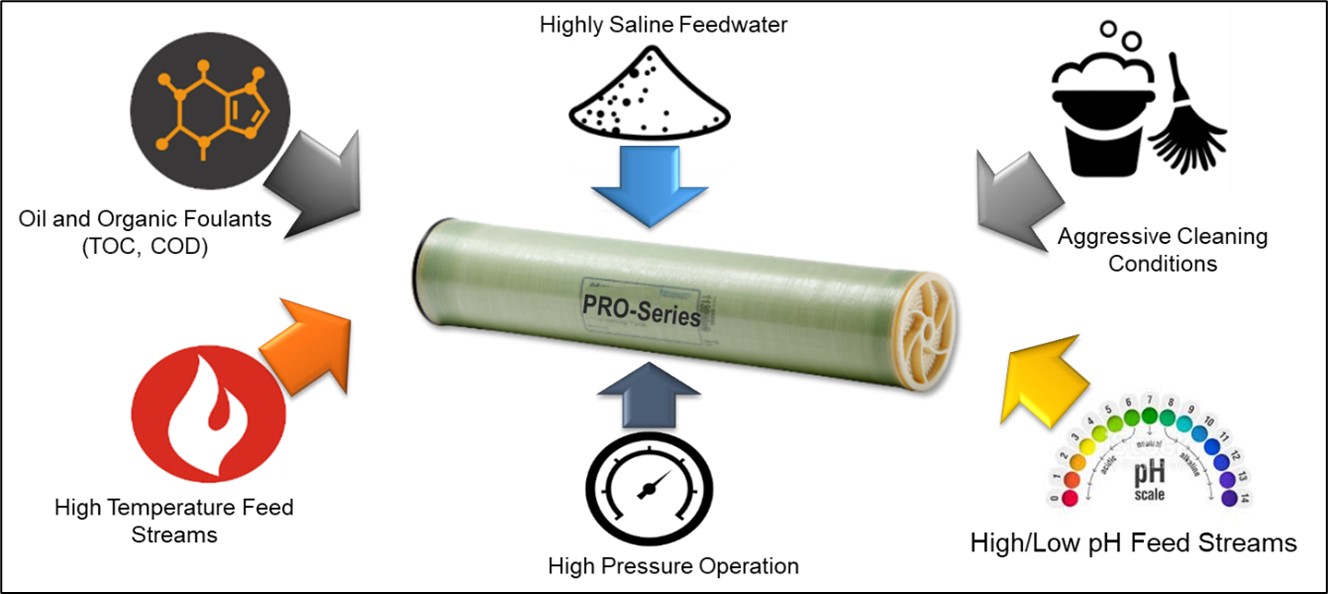

Hydranautics, the global leader in membrane technology has launched an entirely new range of specialty membranes: the PRO series. In today’s scenario of water scarcity and stringent environment regulations, the PRO series is the best ensemble of robust RO-NF membrane solutions for treating challenging industrial wastewaters. This series is specifically designed to address the key challenges faced by wastewater treatment plants and help companies to achieve their Minimum Liquid Discharge (MLD) and Zero Liquid Discharge (ZLD) commitment.

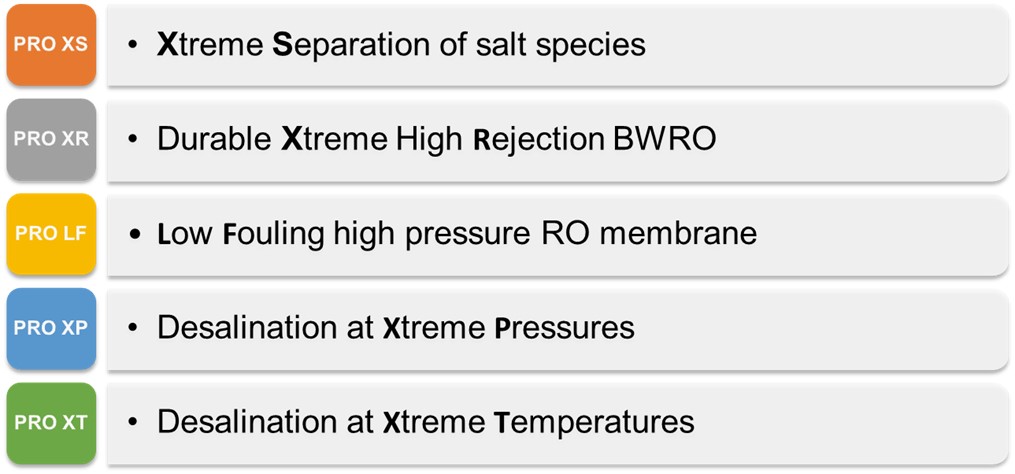

The PRO series comprises the PRO-XR, PRO-LF, PRO-XS, PRO-XP and PRO-XT products with distinct key features such has high chemical tolerance, high fouling resistance, extra ion selectivity and the ability to operate at high feed pressure.

There is a growing need worldwide to treat industrial waters to achieve zero or minimum liquid discharge. In most cases, the treatment is very complicated and has many processes to achieve the desired water recovery.

Industrial wastewater reclamation is moving to higher membrane systems recovery to minimize costs and protect the environment and reduce the size of thermal evaporators and crystallizers.

New membranes have been developed by Hydranautics to address challenges associated with ZLD

- PRO-XS membranes have been developed and demonstrated to concentrate specific divalent ions such as SO4,PO4, Ca and Mg into the concentrate stream and pass monovalent ions into the permeate such as Cl, HCO3, NO3, F

- PRO-XP membranes can operate up to 1800 PSI (124 bar) and reach brine concentrations as high as 148,000 mg/l of TDS, thus reducing evaporation costs in ZLD

- PRO-LF membranes with a low fouling coating have been applied to SWRO type membranes to make them more hydrophilic and reduce fouling by hydrophobic oils and hydrocarbons and surfactants found in industrial wastes, thus lowering energy and cleaning costs

- PRO-XT membranes allow you to operate at higher continuous service temperatures (up to 85-90°C) with a 1200 psi limit at 25°C and 200 psi limit at 90°C

Use of Hydranautics’ PRO membrane series empowers customers globally to make sustainable industrial wastewater treatment choices that can be easily incorporated into their existing wastewater treatment plants. To know more about how Hydranautics is bringing in path breaking Integrated Membrane Innovation in the field of Wastewater treatment , get in touch with your local Hydranautics contact today.

You can find more information here.