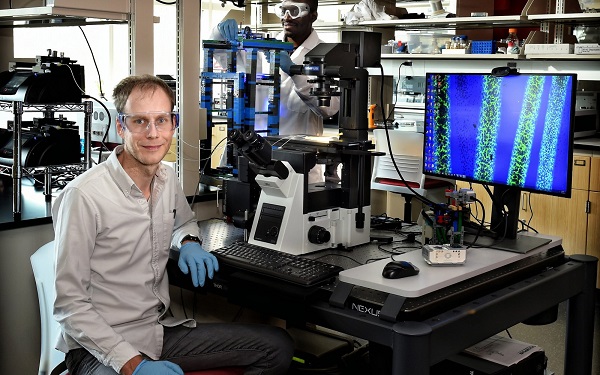

Physical chemist Martin F. Haase is specialized in nano-structured membranes obtained from recently discovered so-called ‘bijels’. The material shows strong potentials to enhance the efficiency of separation processes. It could play an important role in the extraction of drinking water from sea water, for example.

Self-made problem

Most of the world’s drinking water is used for agriculture. The German soft materials researcher Martin Frodo Haase of the Debye Institute for Nanomaterials Science of Utrecht University wants to find a technical solution for this man-made problem. This already exists, as many areas facing a water shortage are located near the sea, and it is technically possible to desalinate the salt water via an osmotic process. Haase says, “There are around 20,000 desalinisation plants in operation around the world, and together they produce one percent of the total volume of fresh water on earth. But the process is expensive, consumes a lot of energy and requires expensive equipment, such as powerful pumps and stainless-steel pipes that can resist corrosion. I want to improve the technology, to make fresh water more accessible.”

Separation by reverse osmosis

The most energy efficient way to separate salt from water is via what is known as ‘reverse osmosis’. It uses a membrane that consists of a substrate with an ultra-thin film on its surface that is only 10 nanometres thick. The polymer chains in the film selectively allow water molecules to pass through, while holding back the salt molecules. But the process requires high pressure, and therefore a lot of energy. The system also must be able to handle the pressure, so the substrate of the membrane needs to be relatively thick, purely to provide the mechanical support.

Two years ago, Haase thought of a better way of designing the membrane: “Instead of using the substrate only for mechanical support, we can extend the thin film deep into the substrate. This would dramatically increase the surface area of the membrane and therefore the achievable freshwater production.” His idea to do that was to manufacture the membrane substrate as a sponge-like material, which allows water to flow inside where the film can separate water and salt. “This type of membrane could potentially desalinate 400 times as much water as state-of-the-art membranes.”

Hardening modelling clay

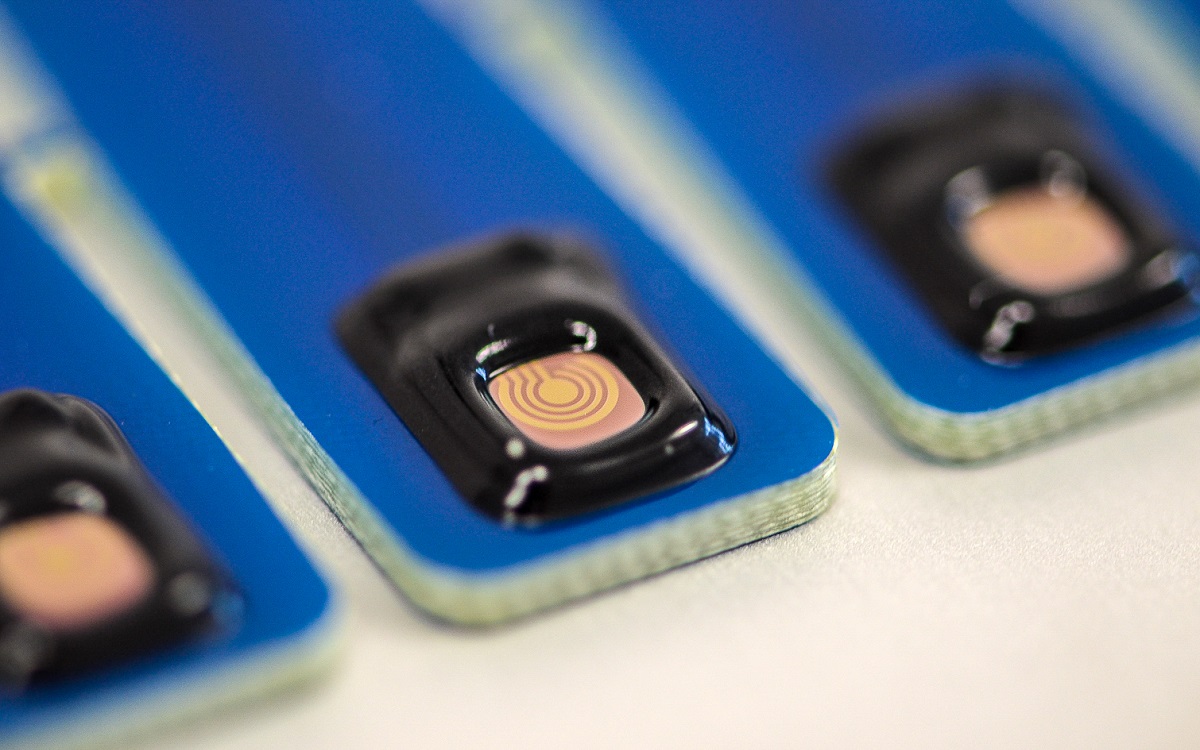

One condition for using a sponge-like membrane is that the salt molecules which remain behind in the structure, and will therefore “clog the membrane”, must be able to be led away from the membrane. Haase is an expert in research into a material that was only discovered in 2005: the bicontinous interfacially jammed emulsion, or ‘bijel’ for short. It is an emulsion of two fluids, with an ultra-thin layer of nanoparticles that hold the surface between the two fluids stable.

Haase: “This bijel normally has the consistency of modelling clay, but when you let it harden, it can be suitable for use as a scaffold for the type of membrane that I’d like to improve. While I was working in the United States, I conducted research that led to the discovery of a new method for producing bijels: STRIPS, or Solvent Transfer Induced Phase Separation.” STRIPS allows for the inexpensive mass production of nanostructured bijels with high internal surface areas and controllable shapes.

Application in other areas

In his various positions, Haase has developed specific aspects of the knowledge he has been applying in Utrecht with funding from an ERC Starting Grant since 2019. And last November, he also received a Vidi grant. “I had already applied the principle of bijels to catalysis for my ERC grant, and now I’m using it to study membranes.”

In addition to desalinating water, bijels may be used to separate other substances in the future. “High surface-area membranes could potentially be used to remove micropollutants from wastewater, or to purify chemicals needed for the industrial production of pharmaceuticals, plastics, adhesives or cosmetics. The most energy-expensive part of these plants is the purification of chemicals.”

Further Information here.