An international team of researchers co-led by Zhijie Chen from the University of Technology Sydney, Australia, has developed a new concept for managing the wastewater from industrial battery recycling facilities. It involves an electrodeposition process to create an electrode material from metal species in the wastewater, which is subsequently used as an electrocatalyst for splitting the same wastewater and generating hydrogen.

Combination of electrodeposition and water splitting processes

‘Critical transition metals, for example, copper, nickel, cobalt, manganese and iron, that are typical pollutants in industrial wastewater are widely used in the design of electrocatalysts for water splitting,’ says Chen. ‘Combination of electrodeposition and water splitting processes enables the synergistic recovery of critical metals and hydrogen from wastewater.” This represents an innovation in modern industrial wastewater treatment that could open a path to lower carbon emissions.

Optimization of a bifunctional catalyst

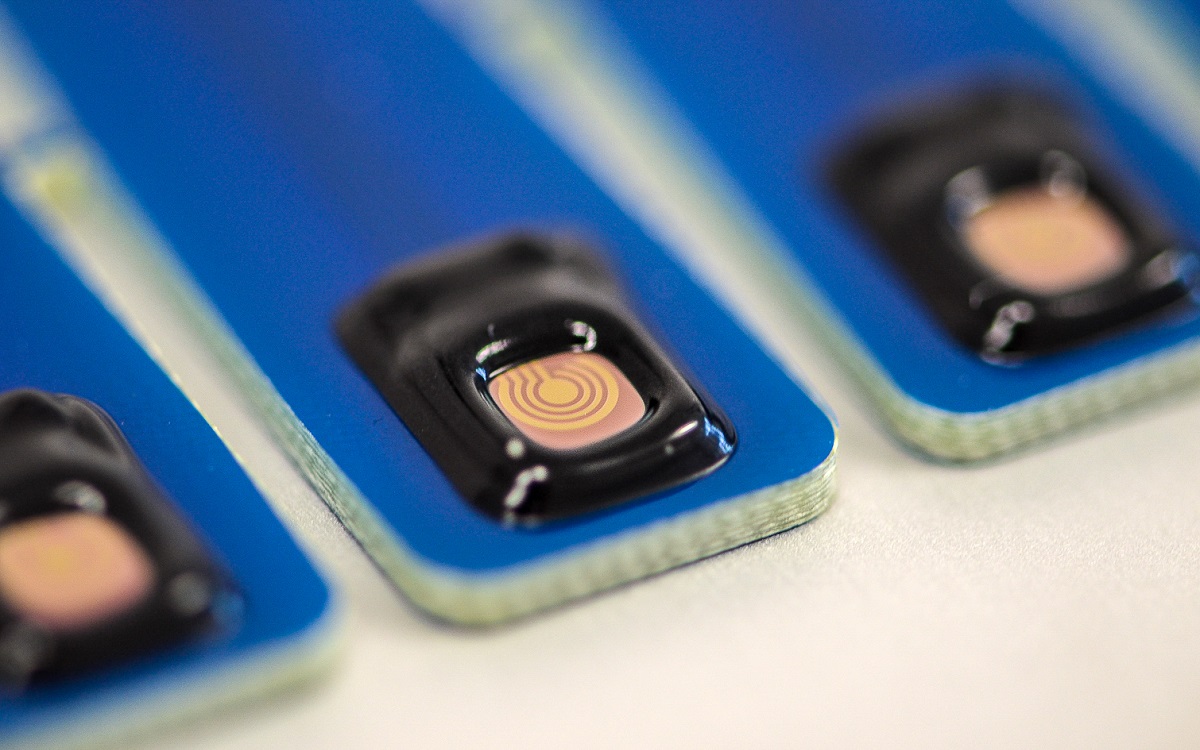

Chen and co-workers’ started off with brown-coloured wastewater from a lithium-ion battery recycling company in Shenzhen, China. They treated it to remove impurities and added dilute HCl and NaOH solutions to regulate its pH. Electrodeposition enabled the team to recover nickel, cobalt and manganese from the wastewater as a NiCoMn layered triple hydroxide. This was then tested as a bifunctional catalyst for electrolysing the post-electrodeposition wastewater. They demonstrated that an optimised version of this catalyst could outperform commercial Pt/C||RuO2 catalysts for post-electrodeposition wastewater electrolysis, with a hydrogen production rate of 2.23 versus 1.78 mg/h at an applied potential of 1.8V.

Avoiding time- and energy-consuming processes

The team says recovering metal ions in wastewater is a cost-effective way to make high-performance electrocatalysts. Directly using post-electrodeposition wastewater as a splitting target avoids time- and energy-consuming wastewater treatment processes, boosting the sustainability of this hydrogen production method. The variation of wastewater properties such as metal ion species, organic species and solid wastes would influence the physiochemical properties of electrodeposited materials and affect the electrocatalytic performance. A pre-treatment process may be required to regulate the properties.

‘The work provides an important step towards appreciating wastewater as a precious reservoir to obtain an electroactive nanomaterial and contribute towards hydrogen production,’ comments Volker Presser who researches sustainable energy systems at the Leibniz Institute for New Materials in Germany.

The researchers plan to integrate solar energy systems into the electrochemical process to further reduce its energy consumption and carbon emissions. They also want to study other types of industrial wastewater to develop a range of resource-recovery processes.

Further information here.